Wastemaster 35° GCE & GCP – Shaftless Screw Screen

SPECO, the wastewater division of WAM, manufactures more shaftless spirals and screw screens than any other producer. Their ISO 9001‑certified facility, combined with SPECO’s value‑engineered design, delivers some of the highest‑quality screw screens on the market.

A single screening system with three core functions serves municipal and industrial plants with flows up to 9 MGD. The base unit screens, conveys, and dewaters debris captured in a channel or delivered to a tank. An optional washing stage can be added to produce cleaner, drier screenings and return more organics to the process. Independent testing has verified a 52% capture rate for the WASTEMASTER 35° screening system.

Did you know?

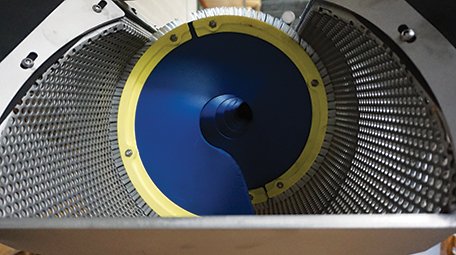

- Segmented brushes mounted on the spiral clean the perforated screen panel.

- Segmented design allows easy brush replacement.

- Brushes can be replaced without removing the spiral from the transport tube.

- Hinged, latched dewatering zone provides safe, tool‑free access.

- Modular design simplifies installation and maintenance.

- Discharge zone available with or without dewatering.

- Optional freeze protection for outdoor operation.

- Optional bagger assembly improves screenings disposal safety for plant personnel.

- Available in tank for pumped flows.

A Speco Wastemaster 35° in operation at a plant.

A Speco Wastemaster 35° in a tank in a plant.

The discharge and motor of the Speco Wastemaster 35°.

The shaftless spiral of the Speco Wastemaster 35° with the segmented brushes on the screw.

Contact Us

Still have questions?

Contact us for quick, expert advice or request a callback and we’ll get back to you today.